|

|

|

SILVER

BRAZING FILLER METALS WITH FREE CADMIUM

|

|

|

|

Silver

Brazing

Alloys |

|

Chemical |

Composition |

|

Mn |

Ni |

In |

AWS/JIS

Spec

Class |

Reference |

Data |

Density

kg/cm3 |

Application |

| Ag |

Cu |

Zn |

Sn |

Solidus

° C |

Liquidus

° C |

CI-925 |

92.5 |

7.5 |

- |

- |

- |

- |

- |

BAg-19 |

760 |

890 |

|

|

CI-721 |

72 |

28 |

- |

- |

- |

- |

- |

BAg-8 |

780 |

780 |

10.0 |

suitable for furnace brazing in a protective

atmosphere without a flux, very fluid. |

CI-701 |

70 |

20 |

10 |

- |

- |

- |

- |

BAg-10 |

725 |

750 |

9.8 |

used particular for joining sterling silver. |

CI-601 |

60 |

23 |

17 |

- |

- |

- |

- |

|

675 |

695 |

9.8 |

similar to CI-721. with lower temperature on it. |

CI-562 |

56 |

22 |

17 |

5 |

- |

- |

- |

BAg-7 |

620 |

650 |

9.5 |

to minimize stress corrosion cracking of nickel or nickel-base alloys at low brazing temperature. |

CI-502Ni |

50 |

20 |

28 |

- |

- |

2 |

- |

BAg-24 |

660 |

707 |

9.0 |

used to cover long narrow joint. |

CI-4900 |

49 |

16 |

23 |

- |

7.5 |

4.5 |

- |

BAg-22 |

680 |

705 |

8.9 |

with improved brazing characteristics, used in

brazing tungsten carbide tools. |

CI-450 |

45 |

30 |

25 |

- |

- |

- |

- |

BAg-5 |

665 |

745 |

9.2 |

especially for brazing in the electrical industry. |

CI-452 |

45 |

27 |

25 |

3 |

- |

- |

- |

BAg-36 |

640 |

680 |

9.2 |

suitable for brazing ferrous & nonferrous base

metals. |

CI-4553 |

45 |

26 |

21 |

- |

- |

3 |

5 |

|

665 |

685 |

|

proved positive with regard to braze & flow. |

CI-407 |

40 |

300 |

25 |

- |

- |

- |

5 |

|

635 |

715 |

9.3 |

good fluid & flow for welding in compressor part. |

CI-402Ni |

40 |

30 |

28 |

- |

- |

2 |

- |

BAg-4 |

670 |

780 |

8.9 |

used extensively for carbide tip brazing. |

CI-402Sn |

40 |

30 |

28 |

2 |

- |

- |

- |

BAg-28 |

640 |

700 |

9.1 |

with a narrower melting range than other cad-free. |

CI-382 |

38 |

32 |

28 |

2 |

- |

- |

- |

BAg-34 |

649 |

721 |

8.8 |

cad-free, ideal substitute for CI-351&CI-301 |

CI-350 |

35 |

32 |

33 |

- |

- |

- |

- |

BAg-35 |

680 |

750 |

9.0 |

frequently used for production brazing applications |

CI-352 |

35 |

32 |

31 |

2 |

- |

- |

- |

|

660 |

740 |

9.0 |

similar to CI-350, but lower temperature than it. |

CI-300 |

30 |

38 |

32 |

- |

- |

- |

- |

BAg-20 |

650 |

750 |

8.8 |

due to its good brazing properties, cad-free & new

uses for this are being developed. |

CI-302 |

30 |

36 |

32 |

2 |

- |

- |

- |

|

680 |

765 |

8.9 |

similar to CI-300, but higher temperature than it. |

CI-252 |

25 |

40 |

33 |

2 |

- |

- |

- |

BAg-37 |

685 |

770 |

8.7 |

lower silver & economical, used for brazing steel,

copper and brass. |

|

|

|

SILVER

COPPER PHOSPHORUS BRAZING FILLER METALS

|

|

|

Silver

Brazing

Alloys |

|

Chemical |

Composition |

|

AWS/JIS

Spec

Class |

Reference |

Date |

Density

kg/cm3 |

Application |

AG |

CU |

P |

Other

elements |

Solidus

° C |

Liquidus

° C |

CI-P007 |

- |

93 |

7 |

< 0.2 |

BCuP-2 |

705 |

805 |

8.05 |

0% silver, better the filleting of the alloy along the joint

boundaries, reducing the alloy flow on the work surface. |

CI-P008 |

- |

92 |

8 |

< 0.2 |

|

700 |

800 |

8.0 |

0% silver, rapid extensive flow. The flow extend over the

work surface & not easy to be control by the operator. |

CI-002 |

2 |

91 |

7 |

< 0.2 |

BCuP-6 |

645 |

740 |

8.1 |

2% silver, flow is extensive; used on well fitted joints. |

CI-005 |

5 |

89 |

6 |

< 0.2 |

BCuP-3 |

640 |

805 |

8.2 |

5% silver, used as an alternate temperature depressant. |

CI-006 |

6 |

86.8 |

7.2 |

< 0.2 |

BCuP-4 |

645 |

725 |

8.2 |

fast flow & silimar to 5% silver. |

CI-101 |

10 |

84.5 |

5.5 |

< 0.2 |

|

|

|

|

lower silver than CI-151, economical type. |

CI-151 |

15 |

80 |

5 |

< 0.2 |

BCuP-5 |

645 |

770 |

8.4 |

lower soldering temperature & most versatile; more widely

used on various types of work than other copper P alloys. |

CI-P181 |

18 |

74.8 |

7.2 |

< 0.2 |

|

645 |

670 |

8.6 |

lowest temperature & fastest flow in copper P alloys. |

CI-P201 |

20 |

74 |

6 |

< 0.2 |

|

630 |

660 |

8.7 |

more better for quantity brazing to above. |

|

|

|

ULTRA-ALLOY

SOLDERING MATERIALS FOR GLASSES/SPECTACLES

|

|

|

| Particularly developing

ultra-alloy soldering materials, professionally suitable for Glasses/Spectacles

business use, soldering professionally to: High Manganese, Nickel

Alloy, Titanium Alloy, Stainless Steel Alloy, White Copper Alloy...etc. |

| |

| PRODUCTS DETAILS |

| |

| 1. CI-101 Manganese

Nickel. |

| 2. CI-102 Stainless

Steel / White Copper wire. |

| 3. CI-103 Stainless

Steel / White Copper wire. |

| 4. CI-104 High Nickel

Alloy, White Copper wire. |

| 5. CI-106 Stainless

Steel, Stainless Steel . |

| 6. CI-721 High Nickel

Alloy, Titanium Alloy. |

| 7. CI-561 Manganese

Nickel / White Copper wire. |

| 8. CI-301-501 Brass

/ White Copper Alloy. |

|

|

|

HIGH

TECHNOLOGY ELECTRON WIRE MATERIALS

|

|

|

1.

|

99.995

Silver wire |

|

(suitable

to Semiconductor wire ; size from 0.03mm ) |

| 2. |

Silver

alloy wire |

|

(suitable

to Fuse conductivity of electrical equipment ; size from 0.04mm) |

| 3. |

Silver-plated

Copper wire |

| |

(suitable

to Fuse conductivity of electrical equipment ; size from 0.06mm) |

|

|

|

SILVER

FLUX POWDER / PASTE

|

|

|

Silver Soldering

Flux:

This product can be used on silver or other soldering alloys with Liquidus

up to 1800 F.It

is so designed that it can be used to low temperature and extended or

uneven heating treatment.Its performance is still as good even under

low temperature.We recommend you to use this product in the soldering

of stainless steel and copper alloy;under the condition of lower or

higher temperature or extended heating time,it can help the fluidity

of solder,remove any attachment and oil stain.This product meets the

international standards, available in powder or paste,and packaged in

1kg or 30kg barrel. F.It

is so designed that it can be used to low temperature and extended or

uneven heating treatment.Its performance is still as good even under

low temperature.We recommend you to use this product in the soldering

of stainless steel and copper alloy;under the condition of lower or

higher temperature or extended heating time,it can help the fluidity

of solder,remove any attachment and oil stain.This product meets the

international standards, available in powder or paste,and packaged in

1kg or 30kg barrel.

|

|

| |

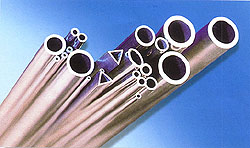

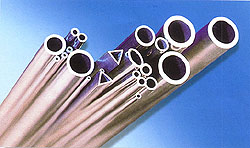

SILVER

ALLOY TUBES |

|

| Alloy No. |

Composition(%) |

| CI-935 |

Ag 93.5, Cu

6.5 |

| CI-925 |

Ag 92.5, Cu

7.5 |

| CI-900 |

Ag 90, Cu 10 |

| CI-835 |

Ag 83.5, Cu

16.5 |

Specifications

as request, tube length with max. to 2.5m

Tube: min Ø12mm x 1.5mm - max Ø30mm x 5mm

Plate: max 50mm width x 5mm thick

2 Wires: Ø6mm/8mm/10mm |

|

|

| |

COPPER

ALLOYS |

|

|